- 首頁

- 周邊輔助設備

- 除濕乾燥機

- 壓縮空氣塑料乾燥機 (無熱式乾燥機) CARD

- CARD G / G FIT

CARD G / G FIT

Material & Workmanship

- Internal material hopper made of mirror polished stainless steel

- External surfaces made of brushed stainless steel

- Air distributer pipe can be demounted from outside the drying hopper

- Completely insulated drying hopper for operating temperature up to 200°C

- Hinged lid with safety catch

- Smoothly integrated sight glass

- Carrying handle with crane attachementpoints (only sizes 3G and 6G)

- Extensive accessories

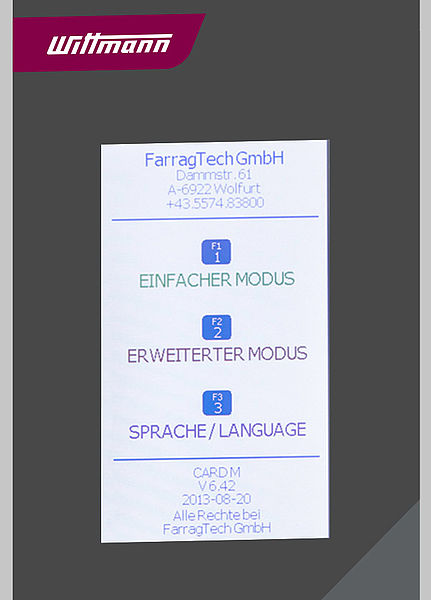

FIT-controller

The FIT-controller communicates with your systems. Connectivity via diverse interfaces enable the operation and recording of alarms and process data from one or more dryers directly at the production machine. The documentation and traceability of the drying process are thus always assured. Communication via ModbusRTU (RS485) or ModbusTCP (Ethernet) offers the option of integrating the dryers in a production data acquisition system (PDA). Recording of data and the control of various processes via a central control station are just as feasible here as a bidirectional control of the dryers with, for example, central loading systems.

Access to the dryer from inside and outside the company is possible at any time via web client. Information about the current drying process can be queried or changed via the IP address. Of course, a password protects against unauthorized access.

As standard, the FIT control also offers the option of recording all important drying data at regular time intervals via a USB stick.

The FIT Controller is also equipped with a touchscreen in addition to the keypad to make operation even more intuitive.

CARD G – small, simple and effective

The CARD G series is ideal for simple drying applications.

Once the temperature has been set and the optional loader has been activated, nothing stands in the way of effective drying.

A simplified SLEEP-mode protects the material from damage by overdrying.

CARD G-FIT – Large amount of features in a small package

The CARD G-FIT is as flexible as your manufacturing processes.

All the advantages of the FIT controller are combined here in the smallest possible size for low throughputs.

- Precise temperature regulation

- Material friendly SLEEP-Mode

- Weekly timer available as optional add-on

- Strobe light for alarms

- Easy alarm analysis through LED with different codes

- Integrated control for one venturi-loader

- Intelligent microprocessor controller with colorful graphic display (FIT)

- Material friendly RAMP-mode

- Material database (recipes)

- Dada logging

- Diverse interfaces for data transfer and for external control

- COUNTDOWN-mode with possibility for production start signal

- Calendar and weekly timer

- Integrated controls for vacuum loader (1 and 2 component)