- 首頁

- 周邊輔助設備

- 除濕乾燥機

- 壓縮空氣塑料乾燥機 (無熱式乾燥機) CARD

- CARD E/S

CARD E/S

The CARD E- and S-series are designed for customers who value flexibility. With these models, it is possible to mount the dryers directly on the machine throat (possible up to CARD 70E/S), to use the units as mobile drying systems or to hang them directly on the wall by means of wall mounting. A total of six sizes are available for even better adaptability - 10E/S, 20E/S, 40E/S, 70E/S, 110E/S and 160E/S.

此系列是為重視靈活性的客戶設計的。此系列可以將乾燥機安裝在任何塑料設備的入料口(CARD 70E以下型號),作為移動式乾燥機。或是直接懸掛在牆上。共有六種尺寸可供選擇,以實現更好的彈性使用-10E / S,20E / S,40E / S,70E / S,110E / S和160E / S。

Material & Workmanship

- Internal material hopper made of mirror polished stainless steel

- External surfaces made of brushed stainless steel

- Air distributer pipe can be demounted from outside the drying hopper

- completely insulated drying hopper for drying temperatures up to 200°C

- Hinged lid with safety catch

- Smoothly integrated sight glass

- Carrying handle with crane attachement points

- Service door for easy cleaning (standard on sizes 110 and 160)

- Extensive optional accessories

CARD E – Cost efficient, simple and effective

The CARD E series is ideal for simple drying applications.

Once the temperature has been set and the optional loader has been activated, nothing stands in the way of effective drying.

A simplified SLEEP mode protects the material from damage by over-drying.

The air flow is controled via a simple radiator valve which is preset. Thus, it can be ensured that not too much compressed air is used, even on CARD E-dryers (for sizes CARD 20E and up).

CARD S – Setting the standard for all other series

The CARD S is as flexible as your manufacturing processes.This series can be considered as our standard, because everything is provided here: comfortable, easy operation, effective technology and our proven FIT controller.

Thanks to digital technology and a proportional valve, air regulation is also extremely precise (for sizes CARD 20S and upwards).

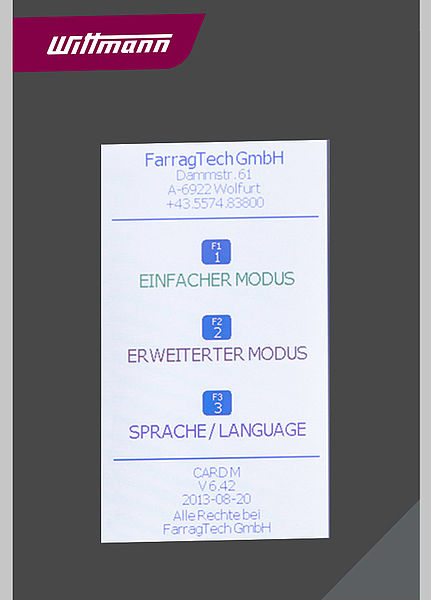

The FIT-controller

The FIT-controller communicates with your systems. Connectivity via diverse interfaces enable the operation and recording of alarms and process data from one or more dryers directly at the production machine. The documentation and traceability of the drying process are thus always assured. Communication via ModbusRTU (RS485) or ModbusTCP (Ethernet) offers the option of integrating the dryers in a production data acquisition system (PDA). Recording of data and the control of various processes via a central control station are just as feasible here as a bidirectional control of the dryers with, for example, central loading systems.

Access to the dryer from inside and outside the company is possible at any time via web client. Information about the current drying process can be queried or changed via the IP address. Of course, a password protects against unauthorized access.

As standard, the FIT control also offers the option of recording all important drying data at regular time intervals via a USB stick.

The FIT controller is also equipped with a touchscreen in addition to the keypad to make operation even more intuitive.

The CARD E series is ideal for simple drying applications.

Once the temperature has been set and the optional loader has been activated, nothing stands in the way of effective drying.

A simplified SLEEP mode protects the material from damage by over-drying.

The air flow is controled via a simple radiator valve which is preset. Thus, it can be ensured that not too much compressed air is used, even on CARD E-dryers (for sizes CARD 20E and up).

- Precise temperature regulation

- Material friendly SLEEP-Mode

- Weekly timer available as optional add-on

- Strobe light for alarms

- Easy alarm analysis through LED with different codes

- Intelligent microprocessor controller with colorful graphic display (FIT)

- Material friendly RAMP-mode

- Material database (recipes)

- Data logging

- Diverse interfaces for data transfer and for external control

- COUNTDOWN-mode with possibility for production start signal

- Calendar and weekly timer

- Integrated controls for vacuum loader (1 and 2 component)

- Integrated controls for second loader to unload the dryer