- 首頁

- 周邊輔助設備

- 除濕乾燥機

- 分段轉輪式空氣乾燥機

- ATON plus

ATON plus G30, G70 and G120

露點低至 -65°C (-85°F)

ambiLED

創新的控制盤使用彩色編碼圖像,持續顯示操作模式和乾燥機的狀態。

Material Database via USB-Stick

Up to 5 material data sets can be imported via a USB interface.

3-Save Process – Intelligent use of Energy

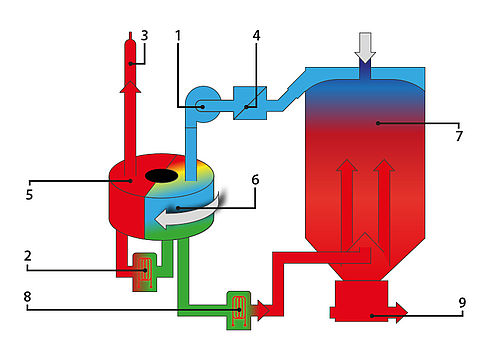

Three separate methods use the heating energy of the dryer to significantly reduce energy consumption. The combination of counter airflow regeneration, radiant heat recovery, and efficient heater design make up the 3-Save Process.

EcoMode – Indexing regeneration during lower water load

During high water loads, continuous wheel mode provides the best dry air conditions. The ATON plus adjusts automatically the regeneration temperature when the material throughput or water load in the plastic resin is reduced. The regeneration works by indexing portions of the wheel and is saving energy.

露點管理

可由使用者設定的露點會自動調整再生溫度,確保達到最大的節能效果。

材料保護功能

在產量減少時自動降低乾燥溫度,避免塑料樹脂過熱或發生熱降解。

- 露點感應器: 露點顯示具有報警功能和啟動露點管理。。

- 回流空氣冷卻器: 回流空氣冷卻盤管整合在過濾器本體內,不僅能提供最高效率,而且容易整修。

- 製程微粒過濾器: 粉塵分離效率高達 99.9%,確保材料加工的光學特性。

- 高溫結構體: 需要更高的溫度才能將製程溫度能力(標準: 130 °C)升高至 180°C(356°F),進行有效率的材料乾燥。

- 製程空氣鼓風機

- 再生加熱器

- 熱交換器

- 回流空氣過濾器

- 再生階段

- 冷卻階段

- 塑料樹脂

- 製程空氣加熱器

- 真空脫氣接頭