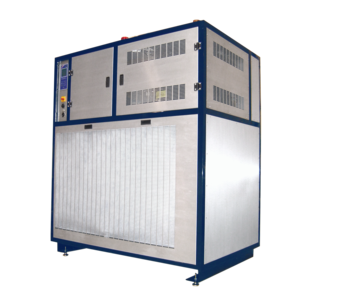

Mould Area Protector

By using the MAP, you can run cold water temperatures of 6°C all year round without a drop of condensation on your enshrouded tools. No matter what climate you are in.

A FIT-controller controls the device and monitors all processes, so the operation is easy and even errors can be easily detected and corrected.

The device is very low maintenance, it only requires occasional cleaning of the filter mat.

Material & Workmanship

- Outer housing made of brushed stainless steel

- High quality refrigeration compressor

- Crane hook

- Pump to remove the condense water from the drip pan

Why mould area protection?

Molded plastic products must be cooled by means of cold water in the cavity of the mold. However, lowering the chilled water temperature below the dew point of the ambient air causes condensation on the mold surface. For example, moisture can lead to defects in the molded product and can permanently damage the mold itself or drastically increase its service intervals - resulting in more rejected products and higher operating costs. However, increasing the chilled water temperature increases the cooling time, slows down the manufacturing process, and reduces overall productivity. The proven Mold Area Protection (MAP) systems have been specifically designed to dehumidify molds and ensure sweat-free production throughout the year, even under tropical conditions. The addition of antifreeze is forgone.

- Easy to operate

- FIT-controller

- All parameters displayed for optimal process monitoring and to ease error detection

- Low maintenance - only periodic cleaning of the filter mat required